From Flower to Shirt

In early spring, flax growers sow the seeds. A 100 days later, the fields turn into a brilliant blue as the ephemeral flax flowers bloom for a short period.

The flax stalks are then pulled up and spread out on the ground for the retting stage, a natural transformation that releases the plant's precious fibers. The retting process can last from two to six weeks, depending on the weather, and only a connoisseur can judge with certainty that it has been completed.

In September, the retted flax is harvested and transformed into large bales, which are trimmed in the fields before being dried.

Next comes the "scutching" stage: the flax fibers are extracted by hand to produce a premium yarn. Thousands of tiny needles then comb the flax until only the purest fiber remains.

The residues are used by other industries (paper, animal feed) to keep the ecological impact to a minimum.

In the factory, the rhythm of the looms resonates without interruption, day and night. Each loom operates at its own speed, and the whole works in harmony. Technicians, fitters and weavers bustle about under the careful supervision of the workshop manager.

While the factory is bustling with activity, concentration reigns in quality control. Every meter of raw fabric passes under the stern eye of the stoppers, who patiently pick up any defects with their needles. This work requires essential qualities: precision, a sharp eye and the ability to concentrate. Rotating blades remove the last lint and impurities from the fabric.This is an essential step for impeccable finishing. Again, residues are collected and recycled.

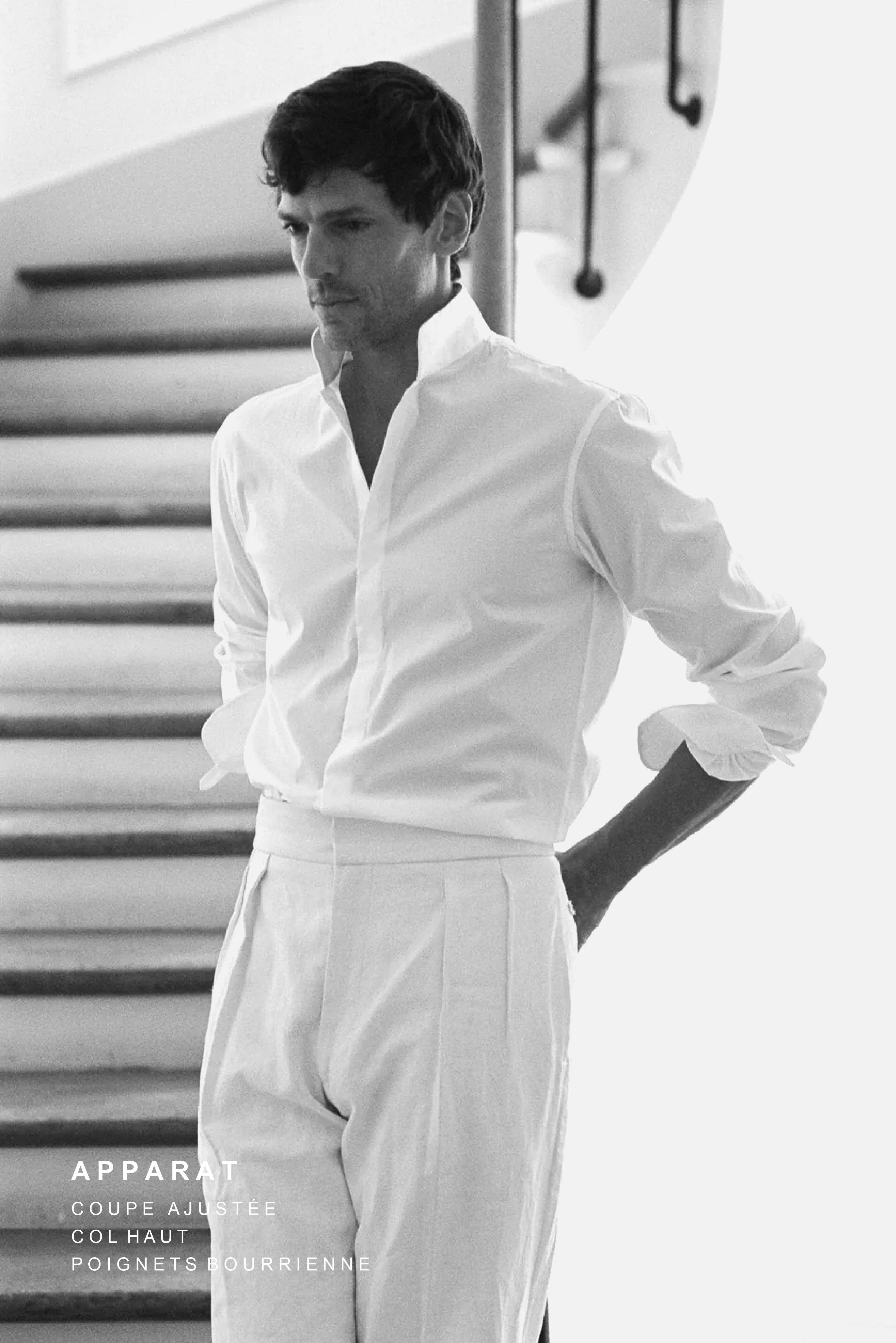

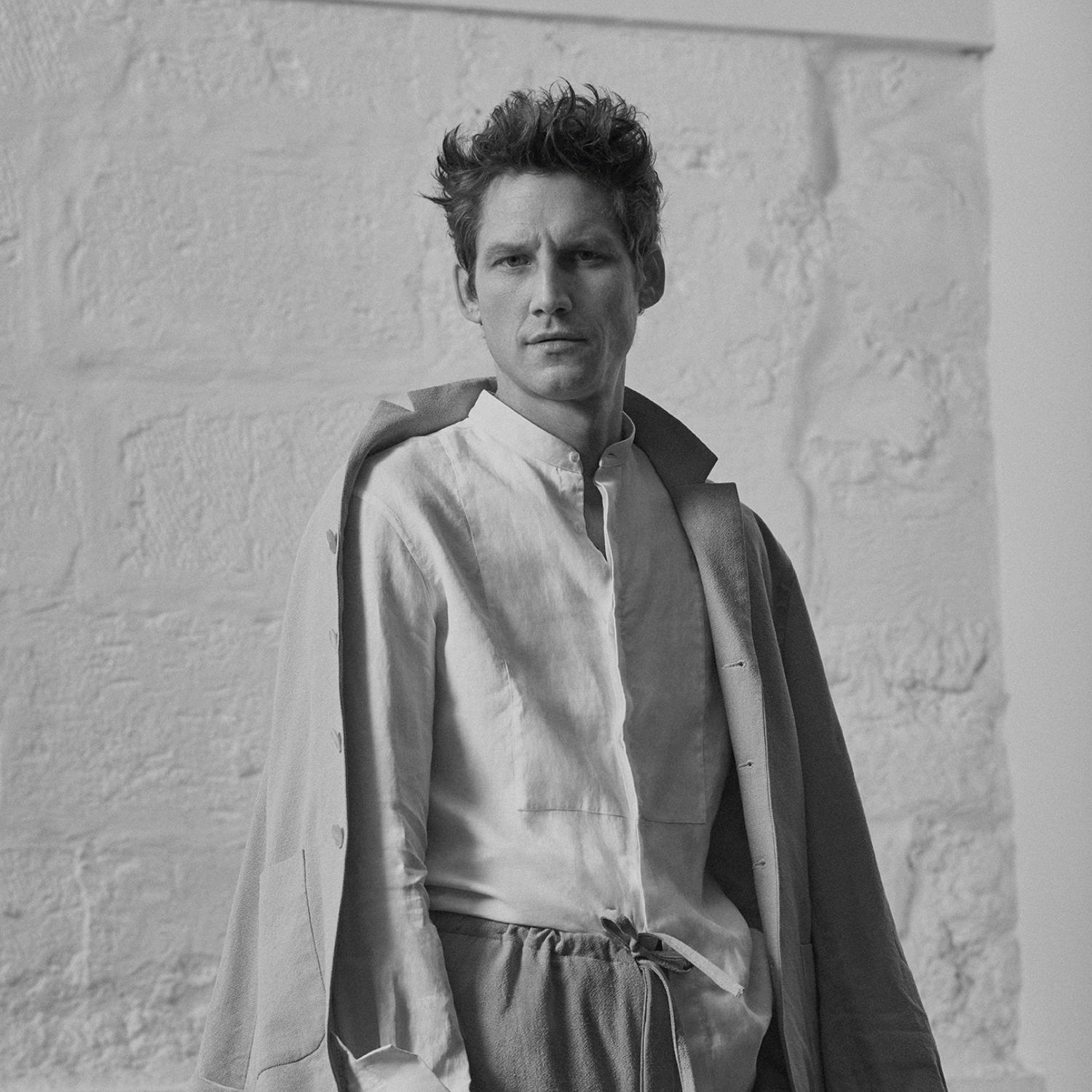

- A rather thick "Plâtre" linen worked with an artisanal finish giving it a Canvas look. Perfect for summer evenings without a jacket.

- A "Stonewash" linen, giving it a supple, flowing look that will come to life on every silhouette.

- A "Light" linen to which we apply a finish made from a blend of resin and wax, giving it a very exclusive "vintage" look.

- A blend of cotton and linen, a replica of the rustic "mixed" fabrics woven in France from the past, but adapted to our times. Half of the fabric is twisted cotton yarn, giving it good resistance and a soft, pleasant feel. The other half is a sky-blue dyed, semi-wetted linen with irregularities, giving the fabric the rustic, authentic look we were looking for

Since 2011, our supplier has been working towards sustainable production.